- Your cart is empty

- Continue Shopping

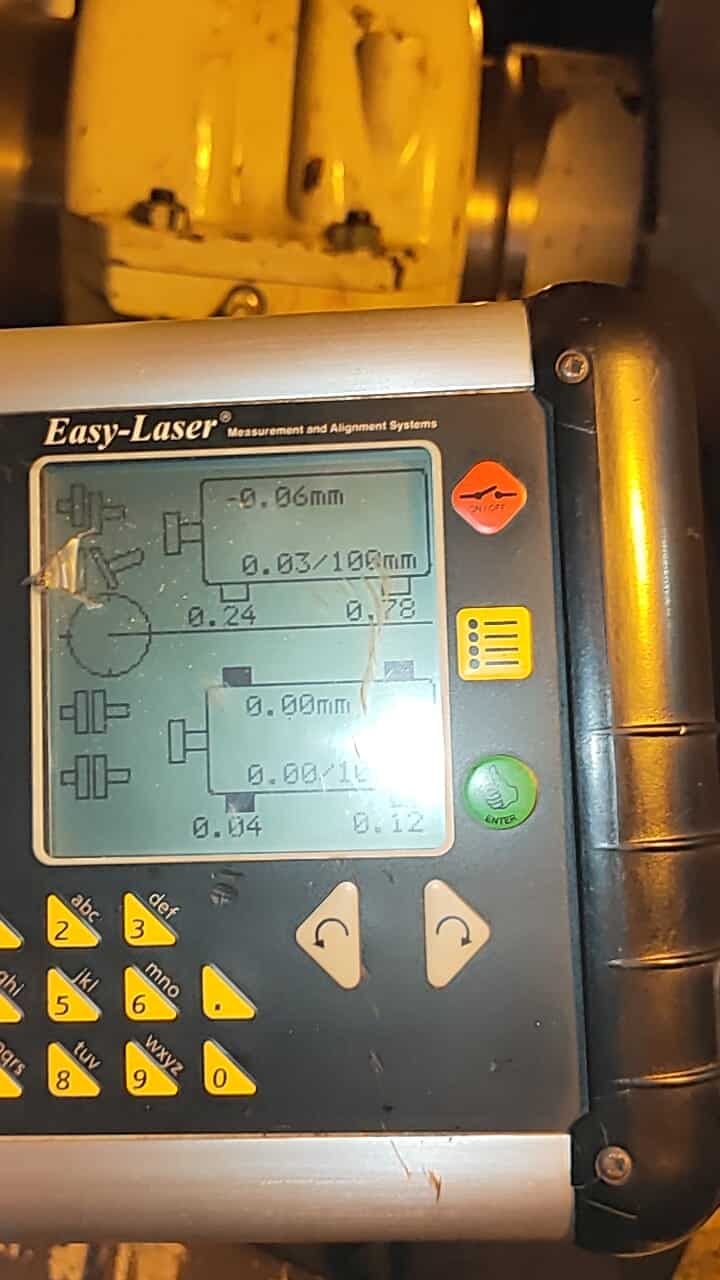

Laser Shift Alignment Systems

- Maintain the life span of the equipment.

- At least 80% energy and fuel savings.

- Reducing maintenance costs for equipment.

- Increasing the efficiency of the equipment.

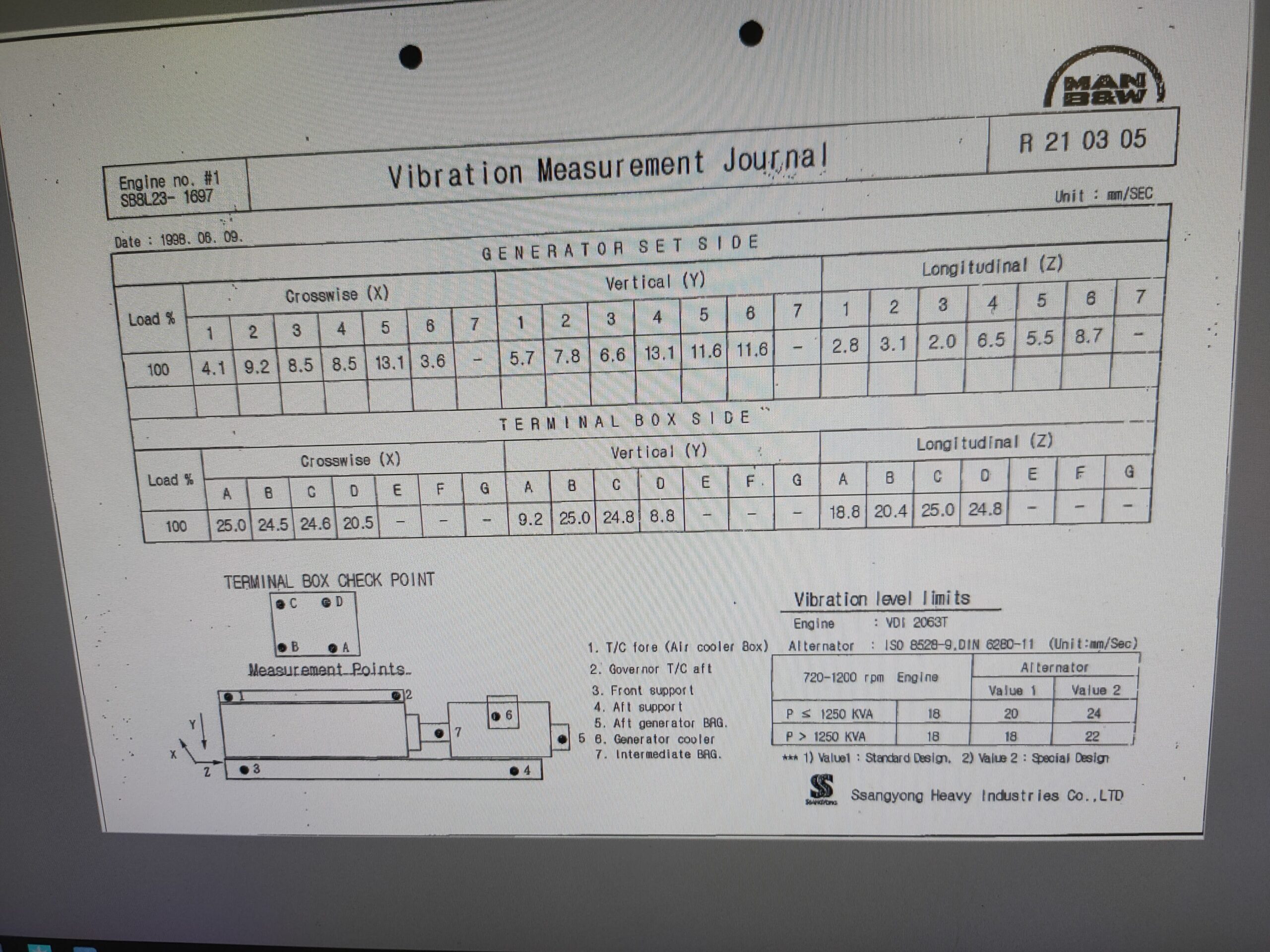

- Preventing equipment from exposure to vibration hazards and its negative impacts, such as:

- Thrust and loading chairs are damaged (ball bearings – roller- bushings).

- (Deflection – fracture – fissure) of crankshaft and the rotor shafts.

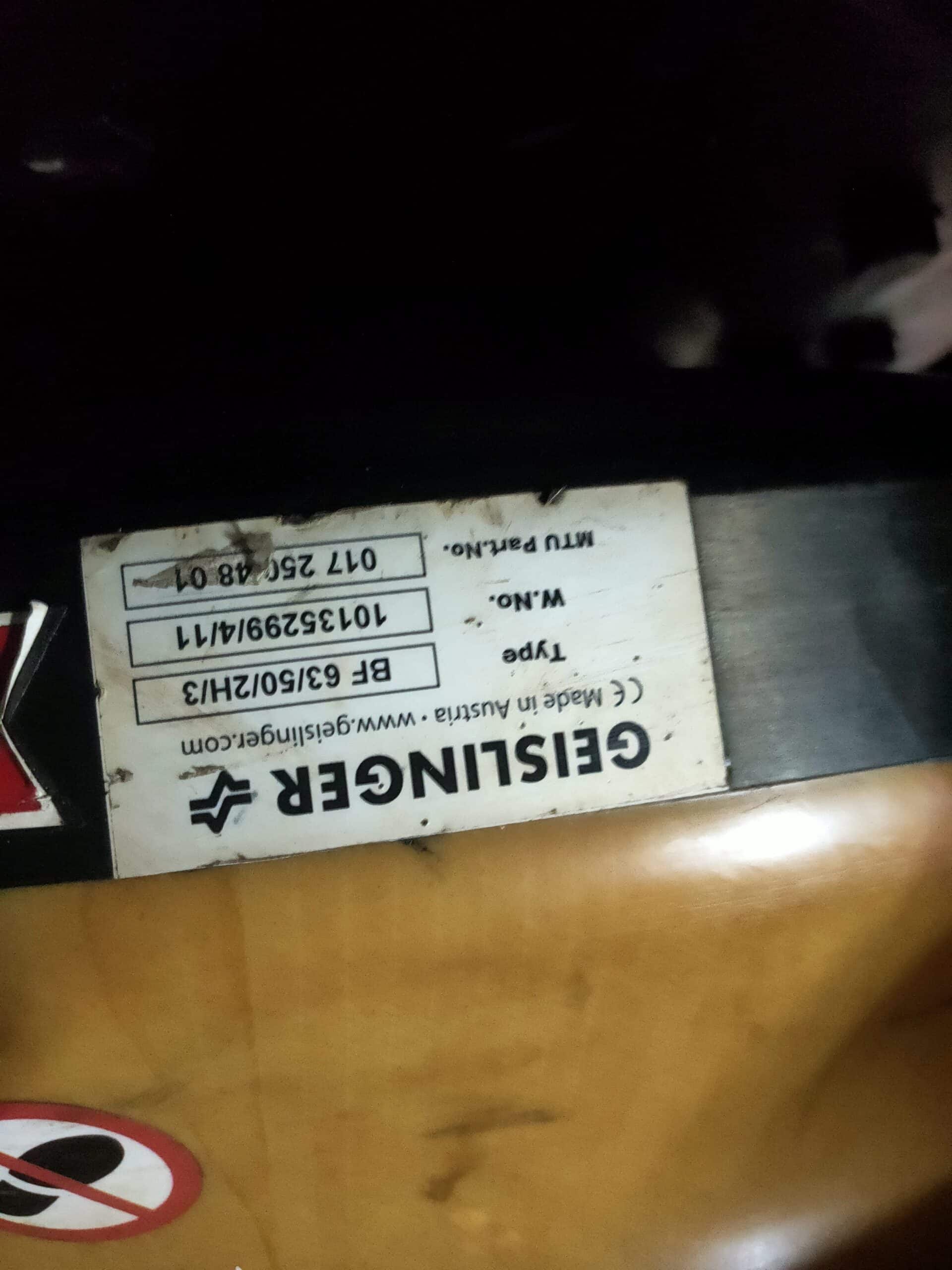

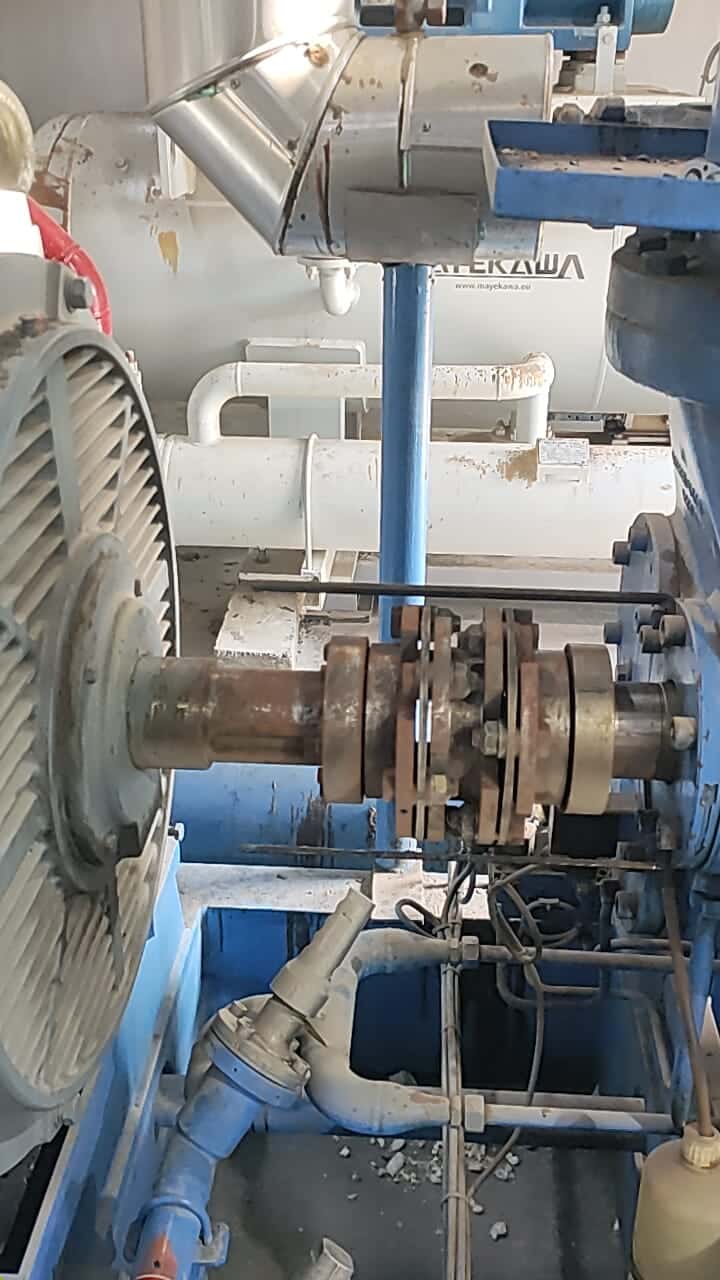

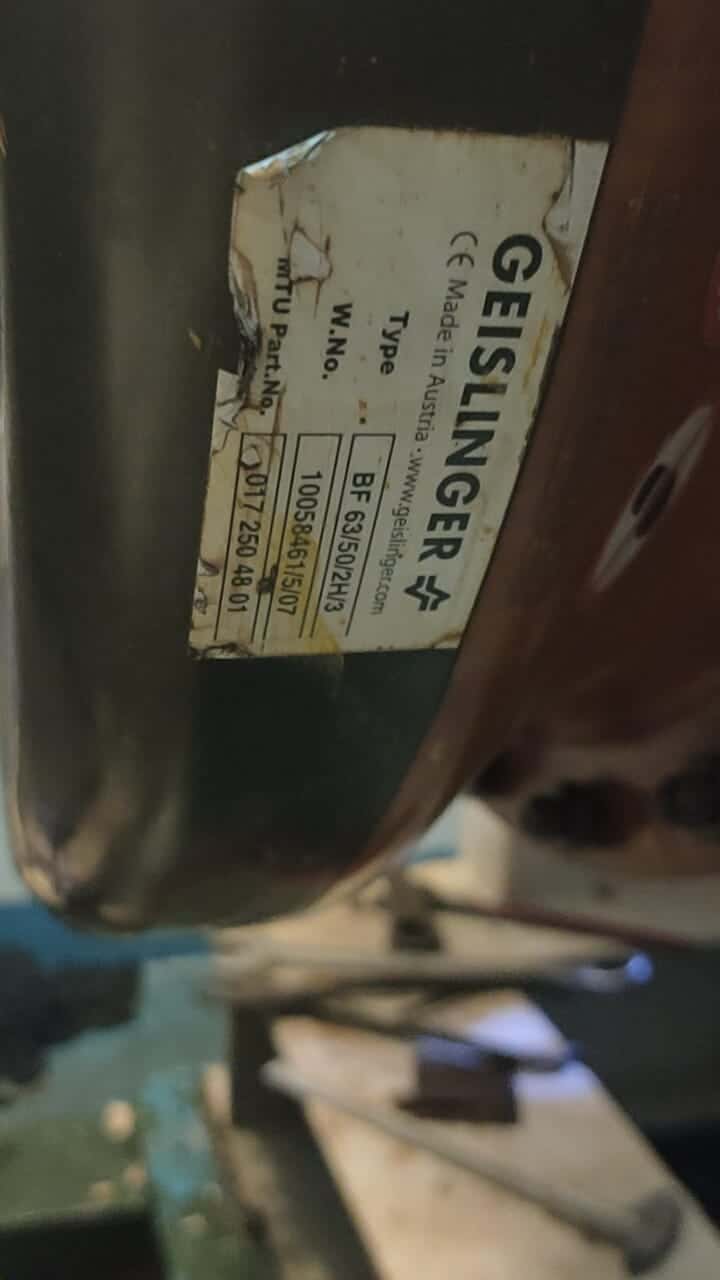

- Damage to the transmitters (coupling – keys – flexible coupling – rubber).

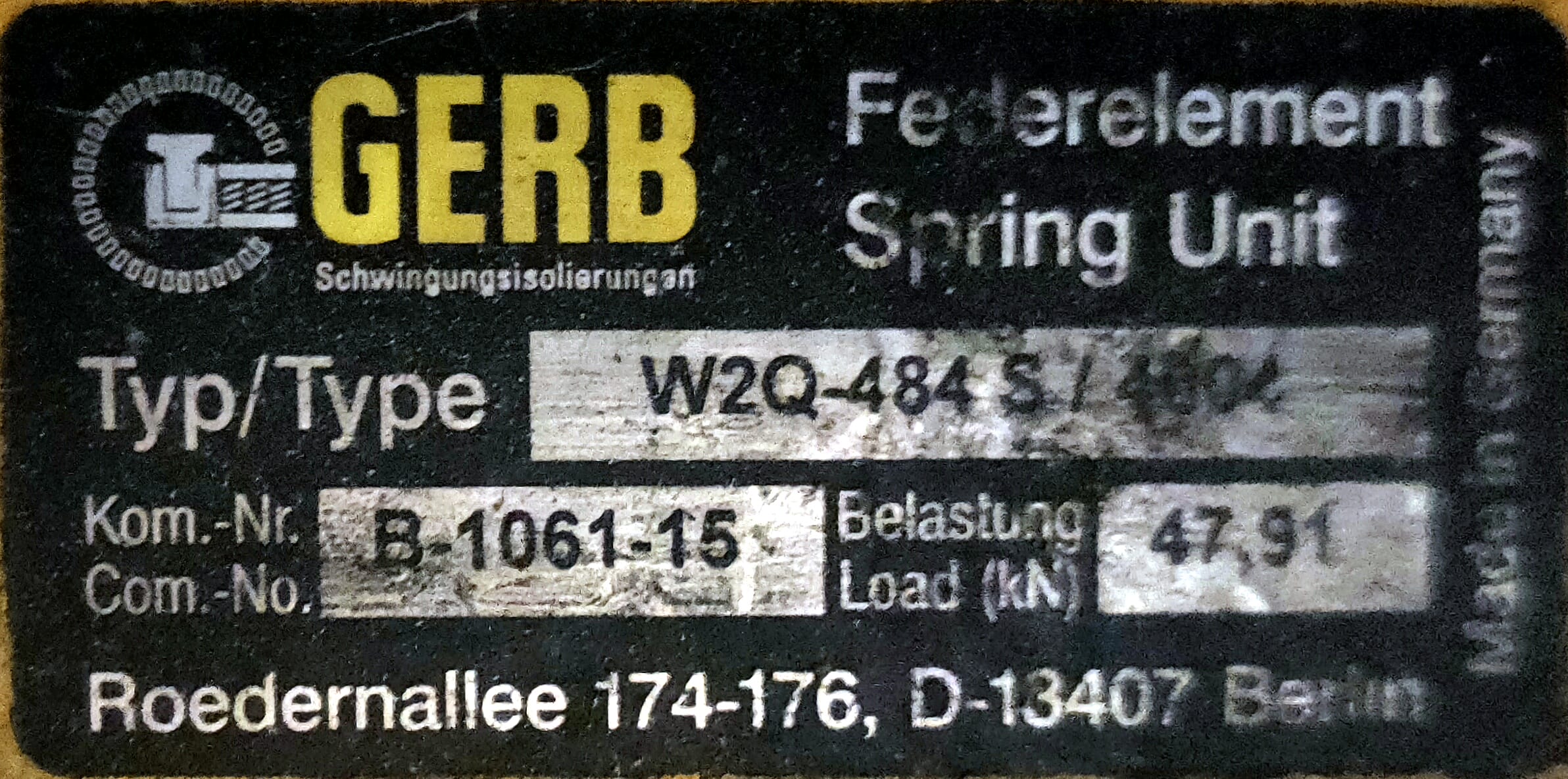

- Damage to The shock absorbers under the equipment.

The most important equipment that we adjust the alignment to:

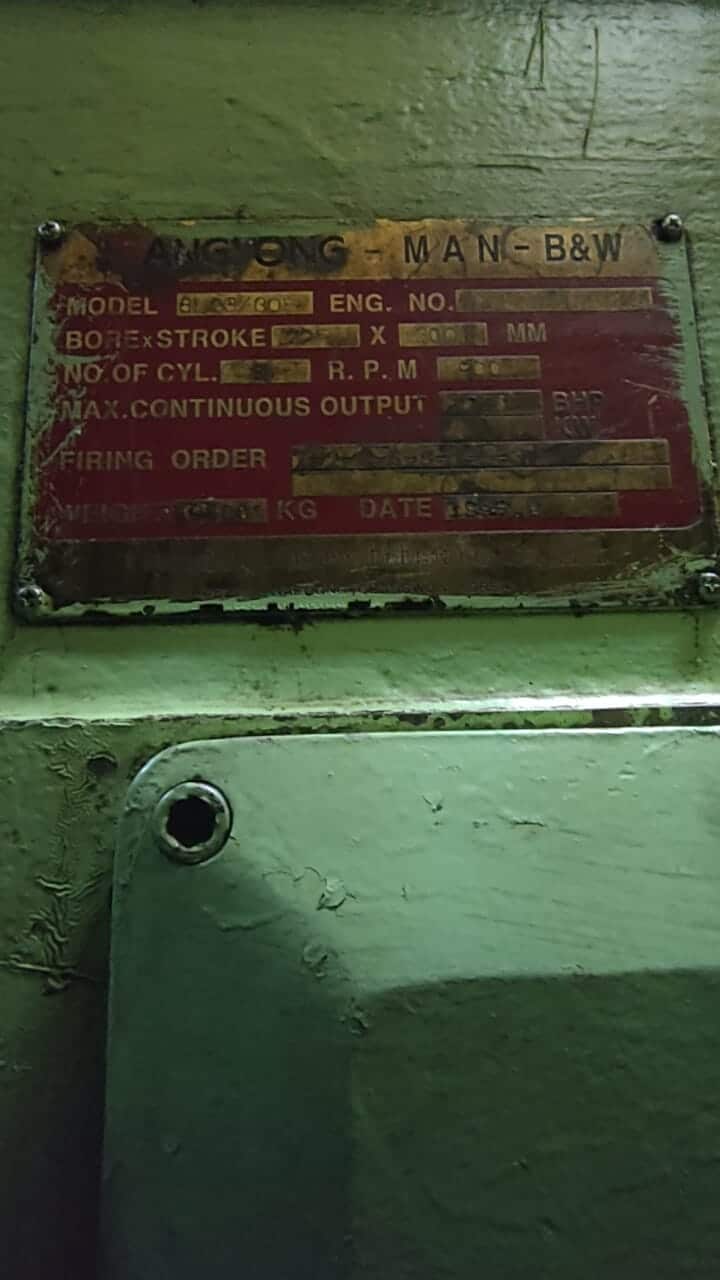

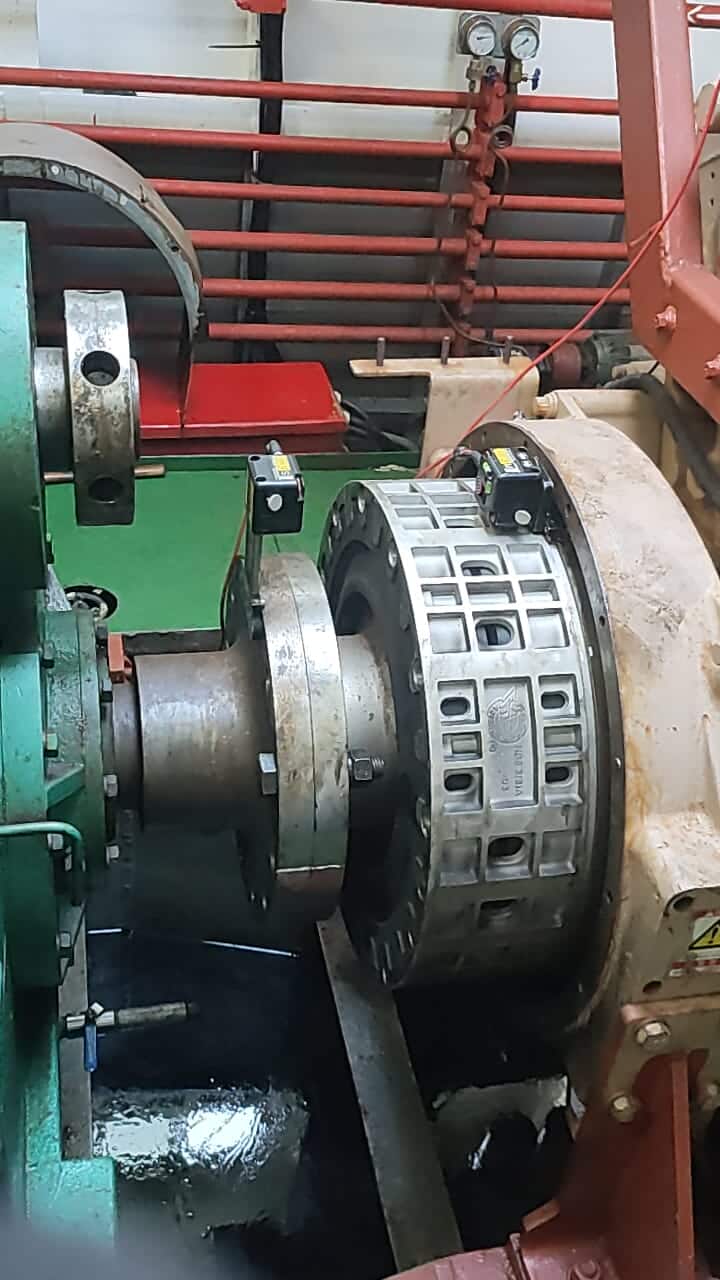

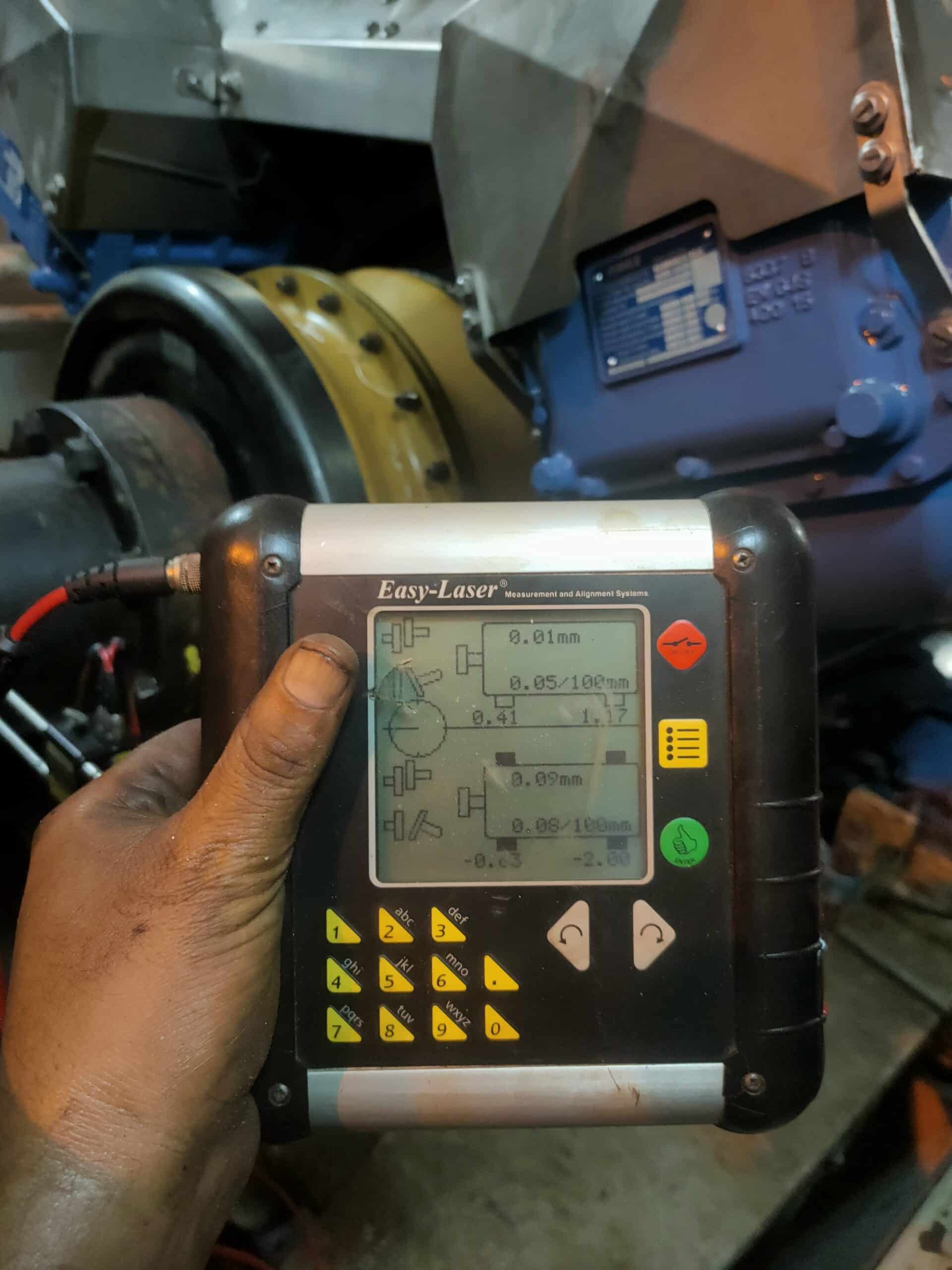

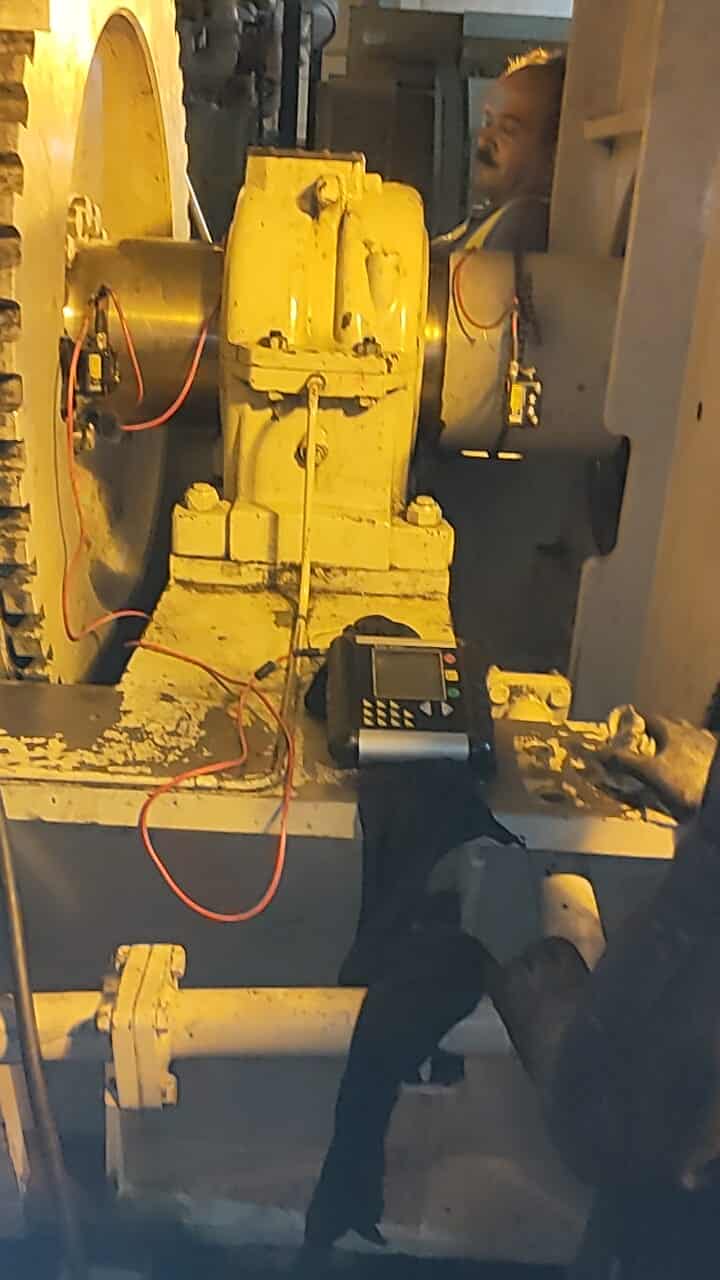

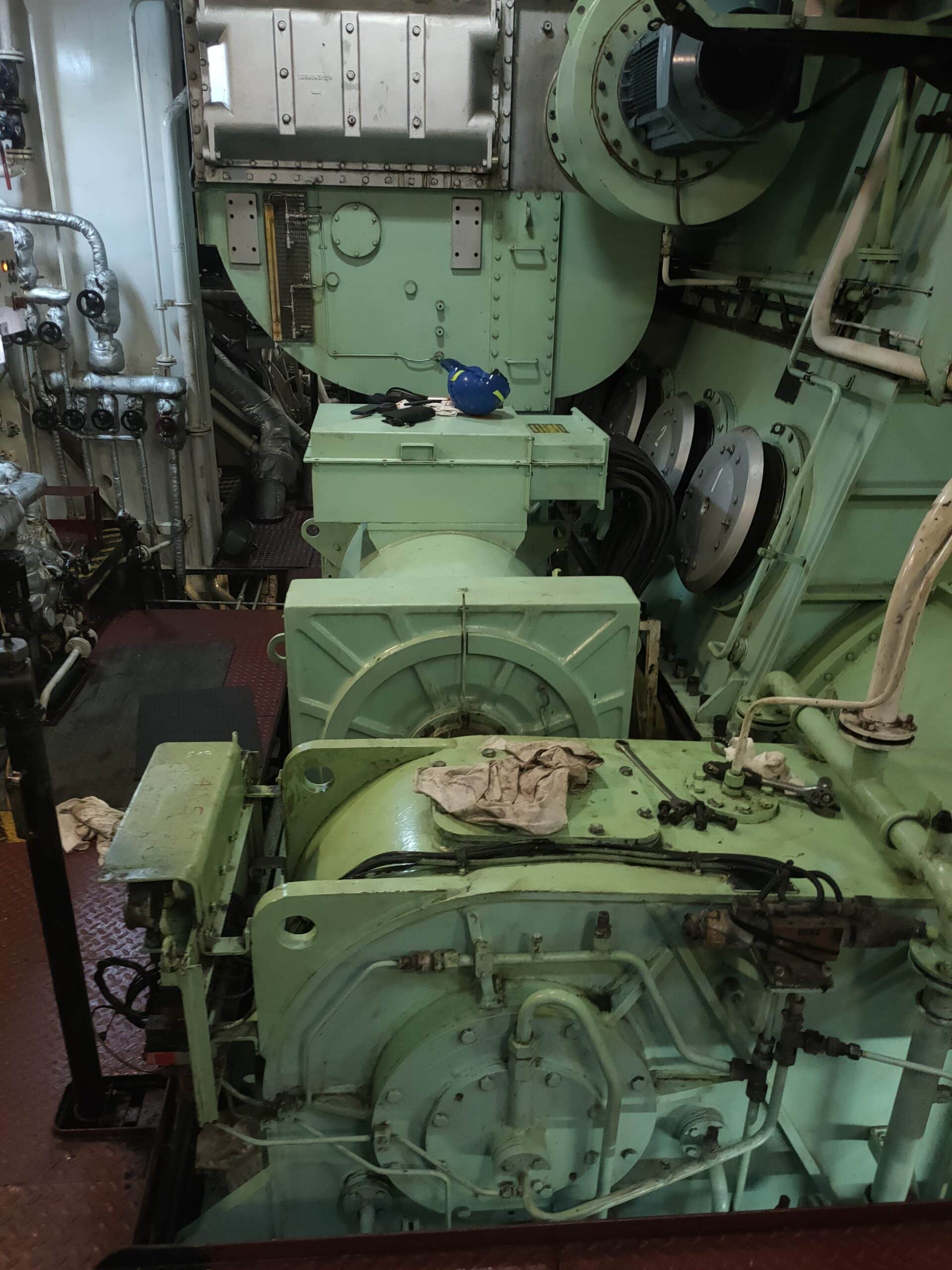

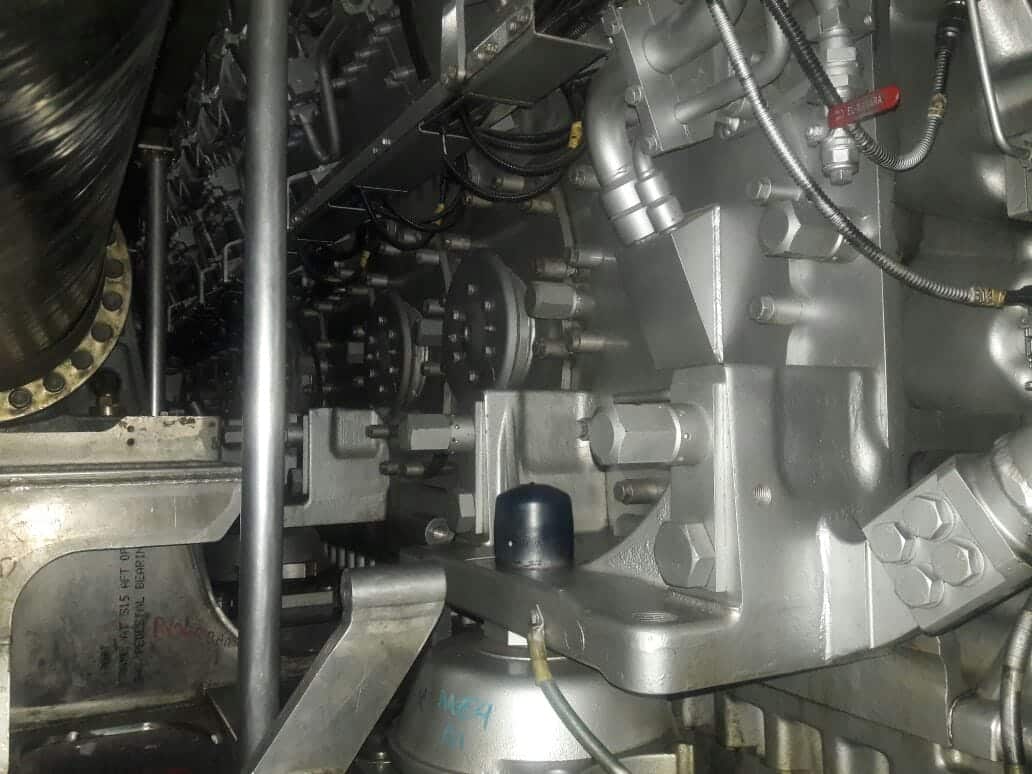

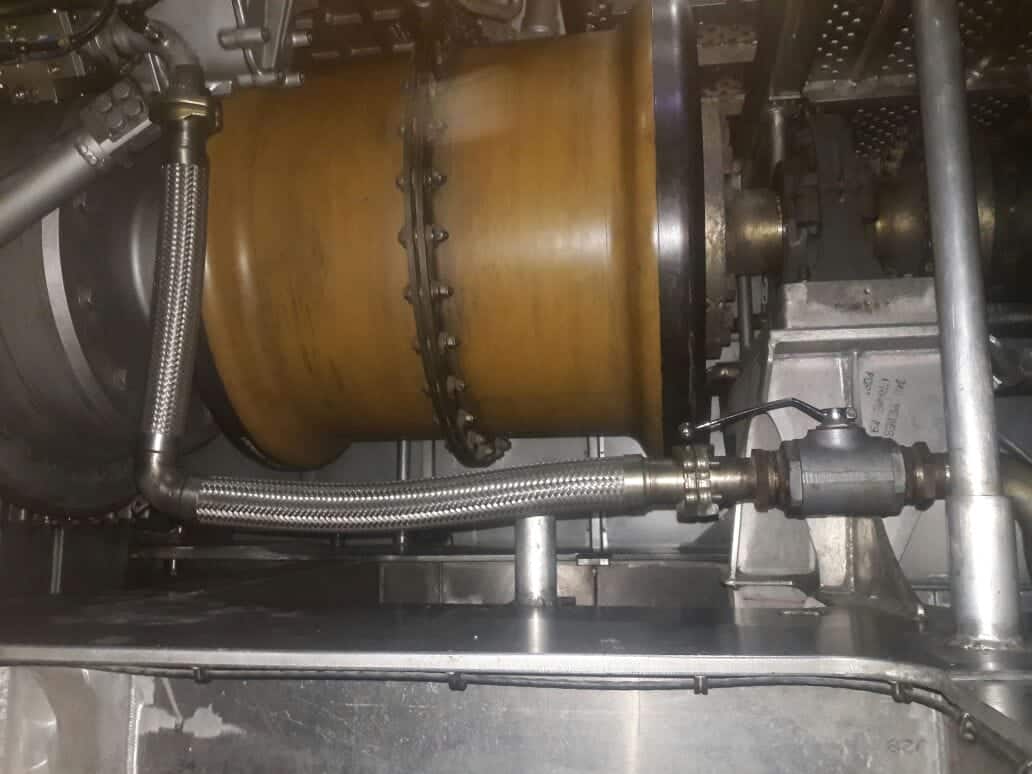

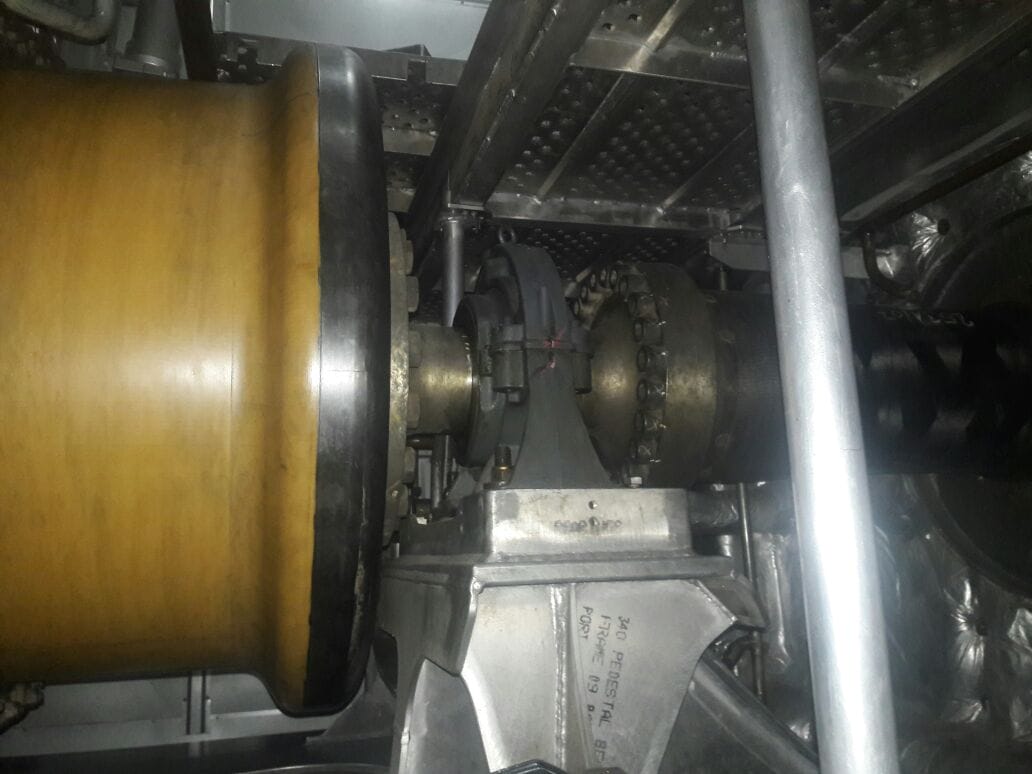

- The propeller shaft and gear box.

- The gear boxes and the main engines.

- The Gearbox with Shaft generator.

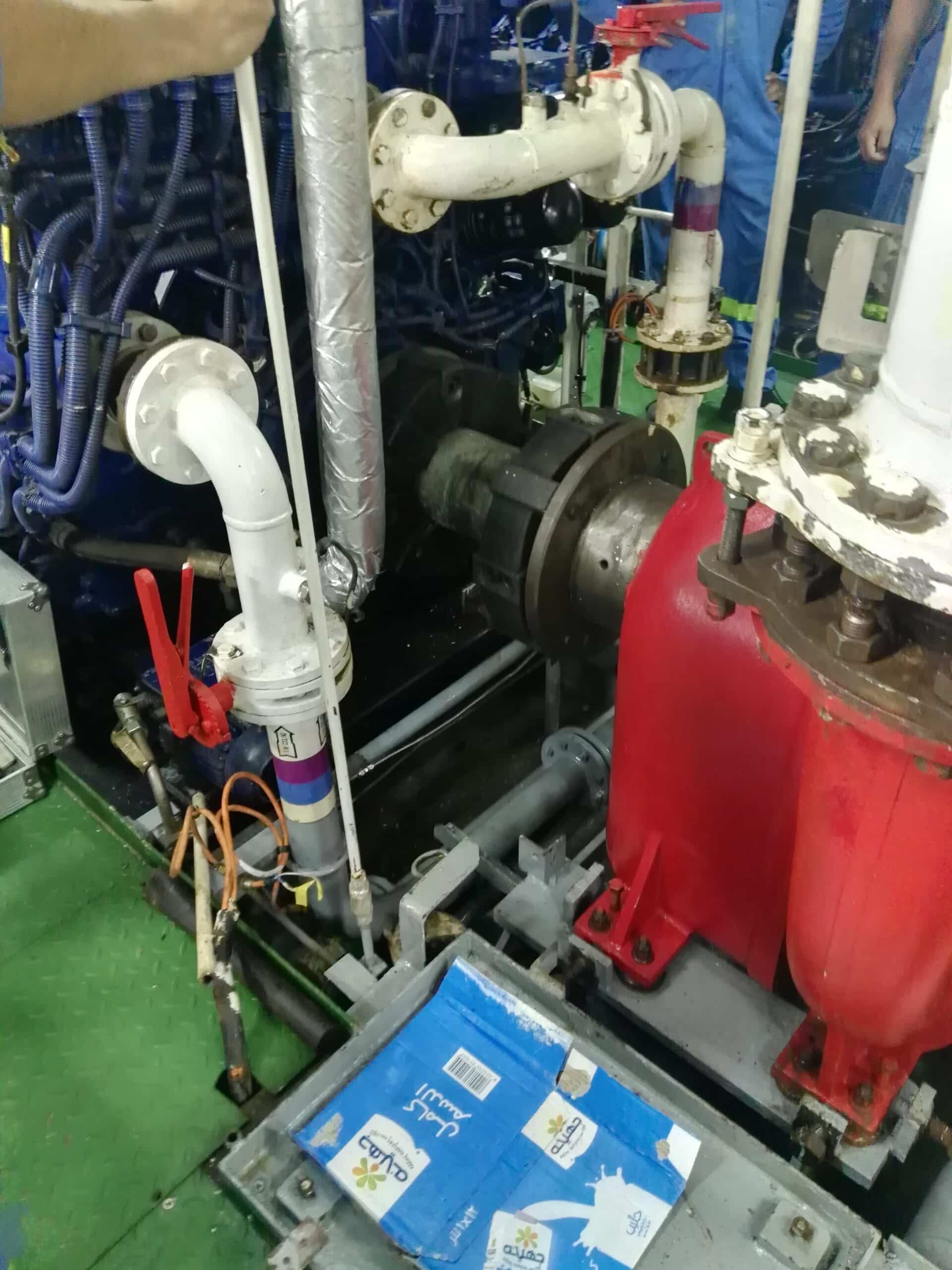

- The Main machines with FIFI PUMPs.

- The Motors with Bow thruster.

- The Motors with hooks winches.

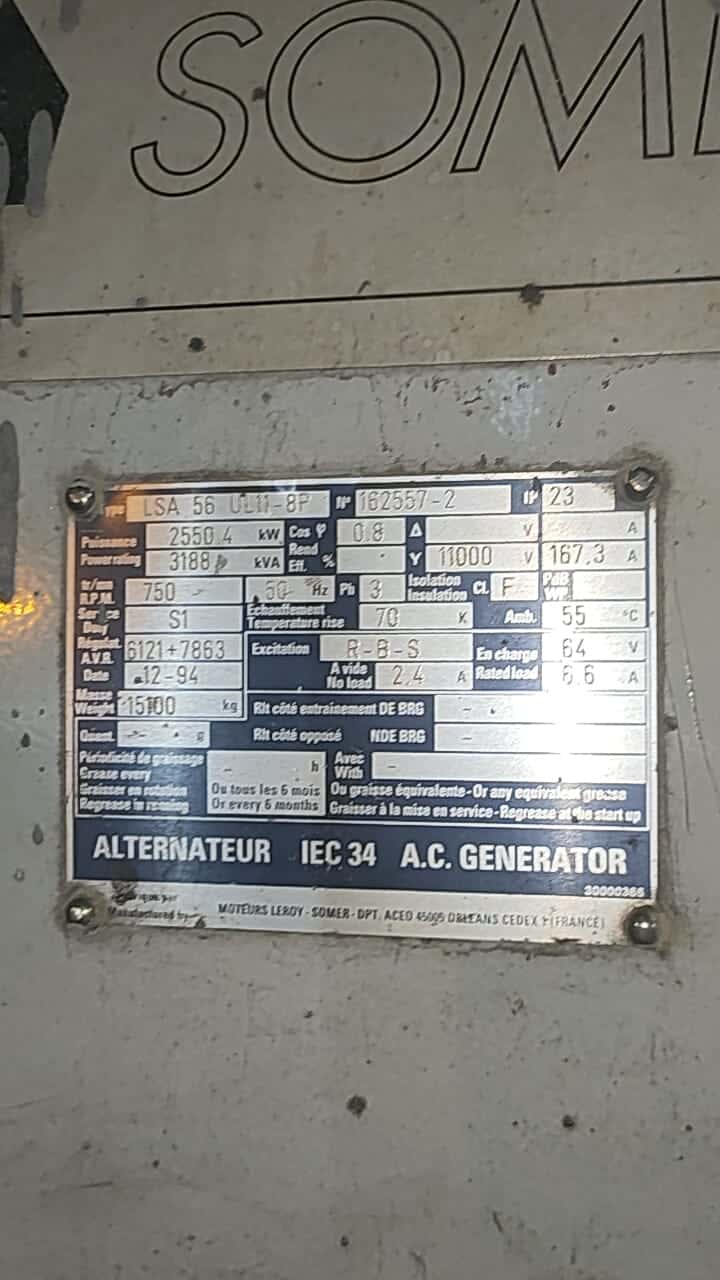

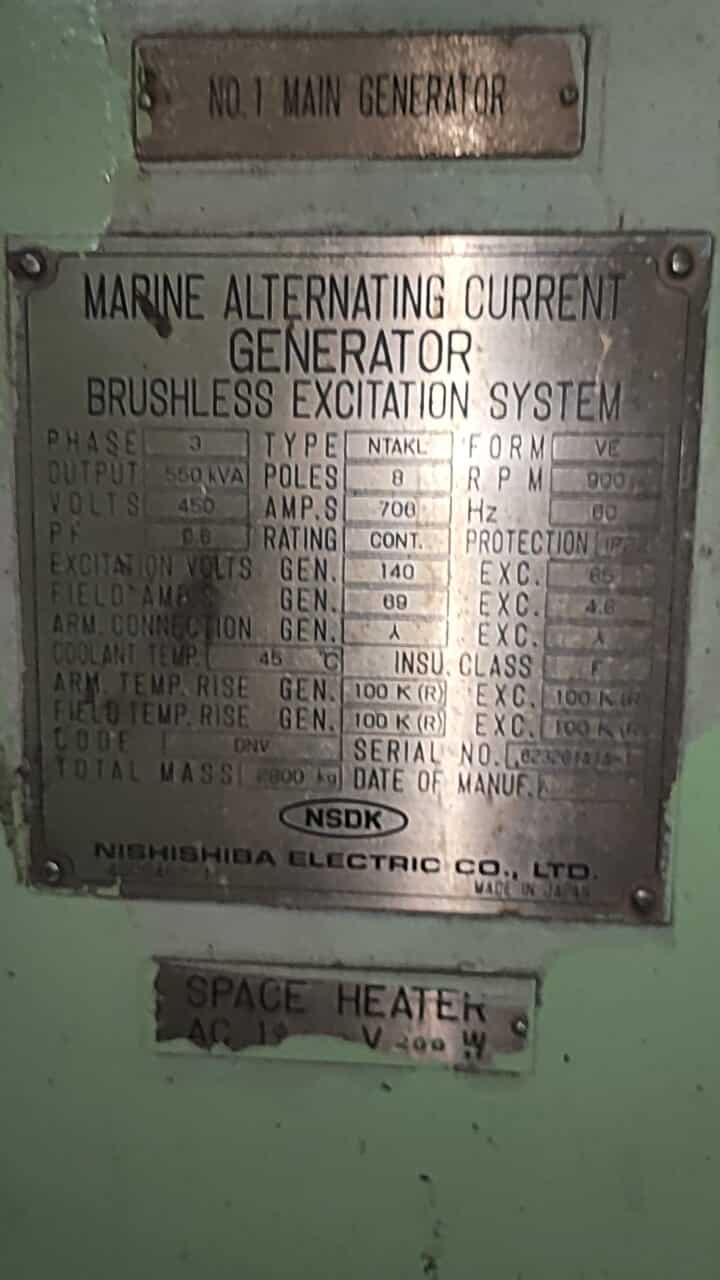

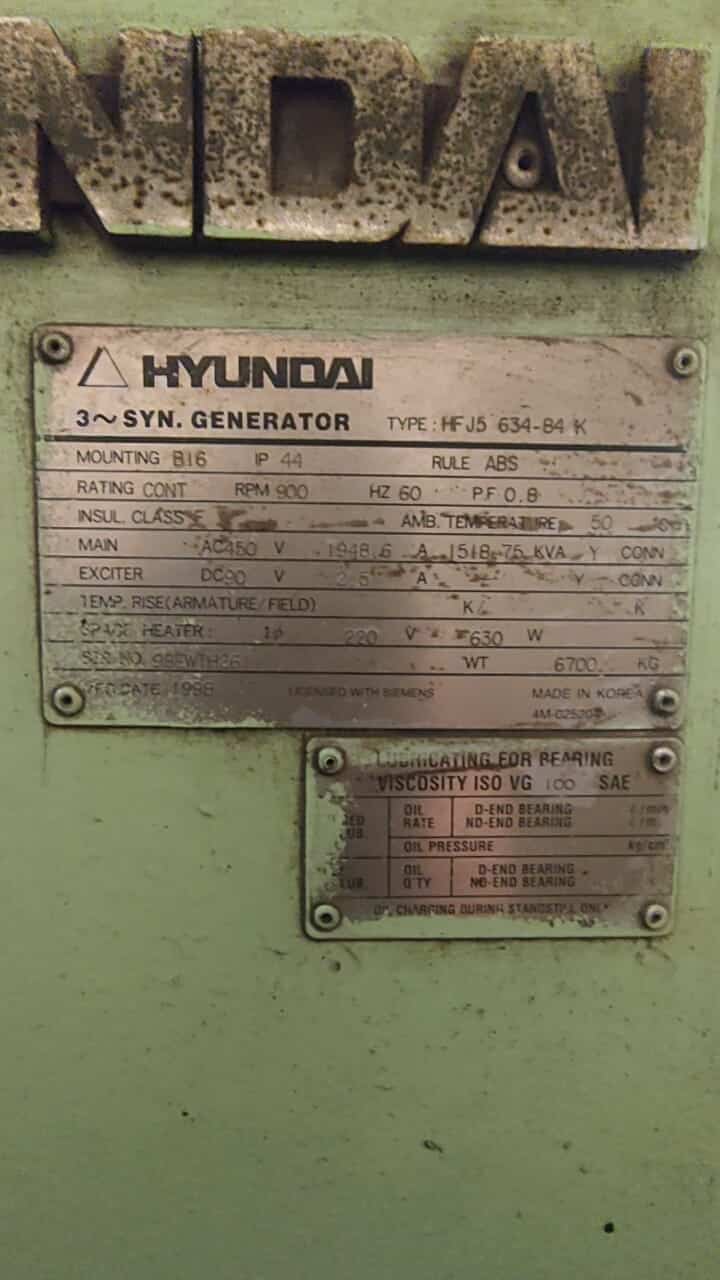

- The generators with lighting diesel.

- The electric motors with pumps.

- The Motors with compressors.

- The motors with belt-driven equipment.

alignment equipment that we adjust

It is Known that there is more than one method used in alignment and determining the optimal method depends on a group of factors and restrictions and we are distinguished by the presence of huge experiences in all methods of alignment and in determining the most appropriate methods for each process separately and these methods are:

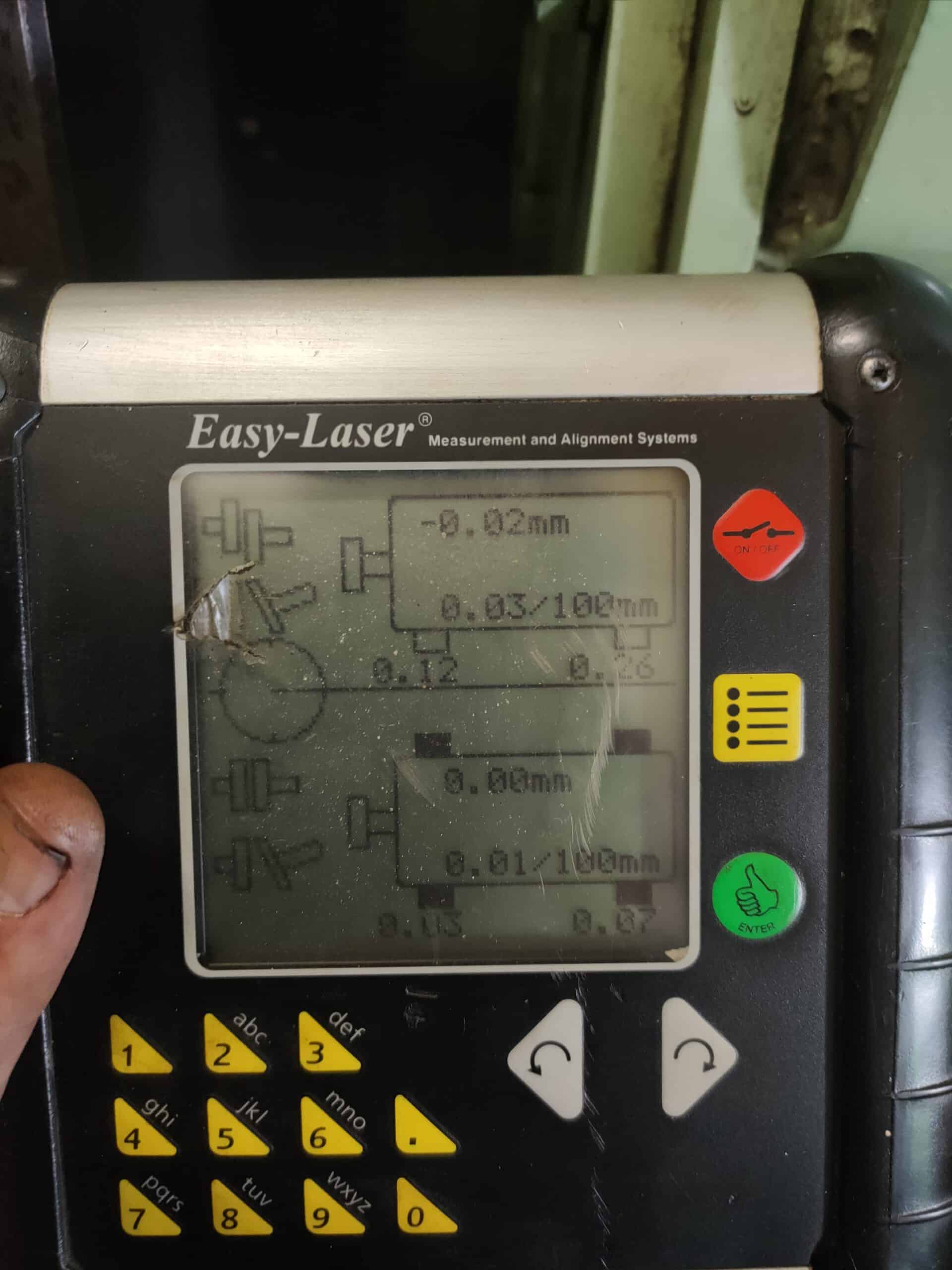

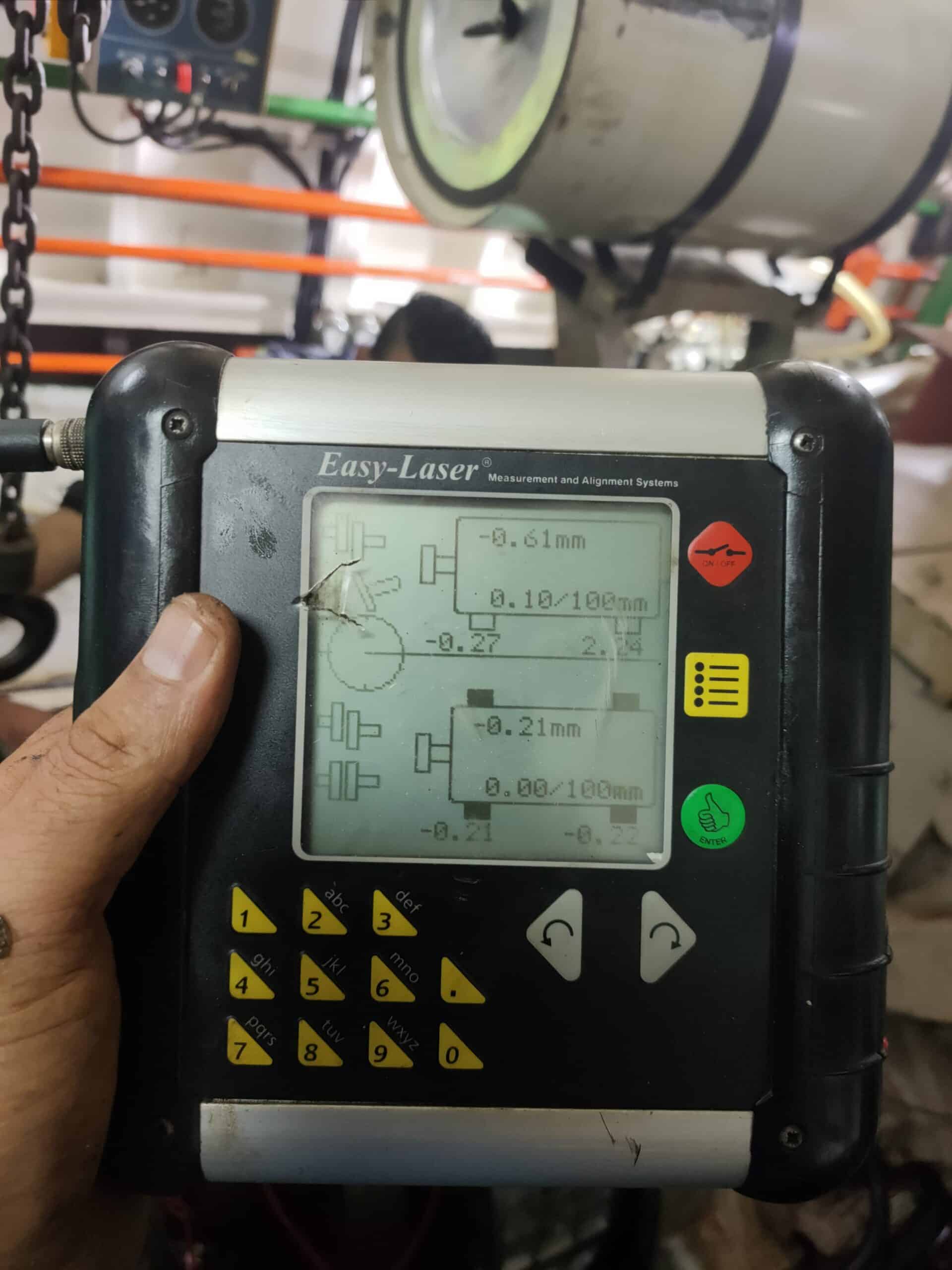

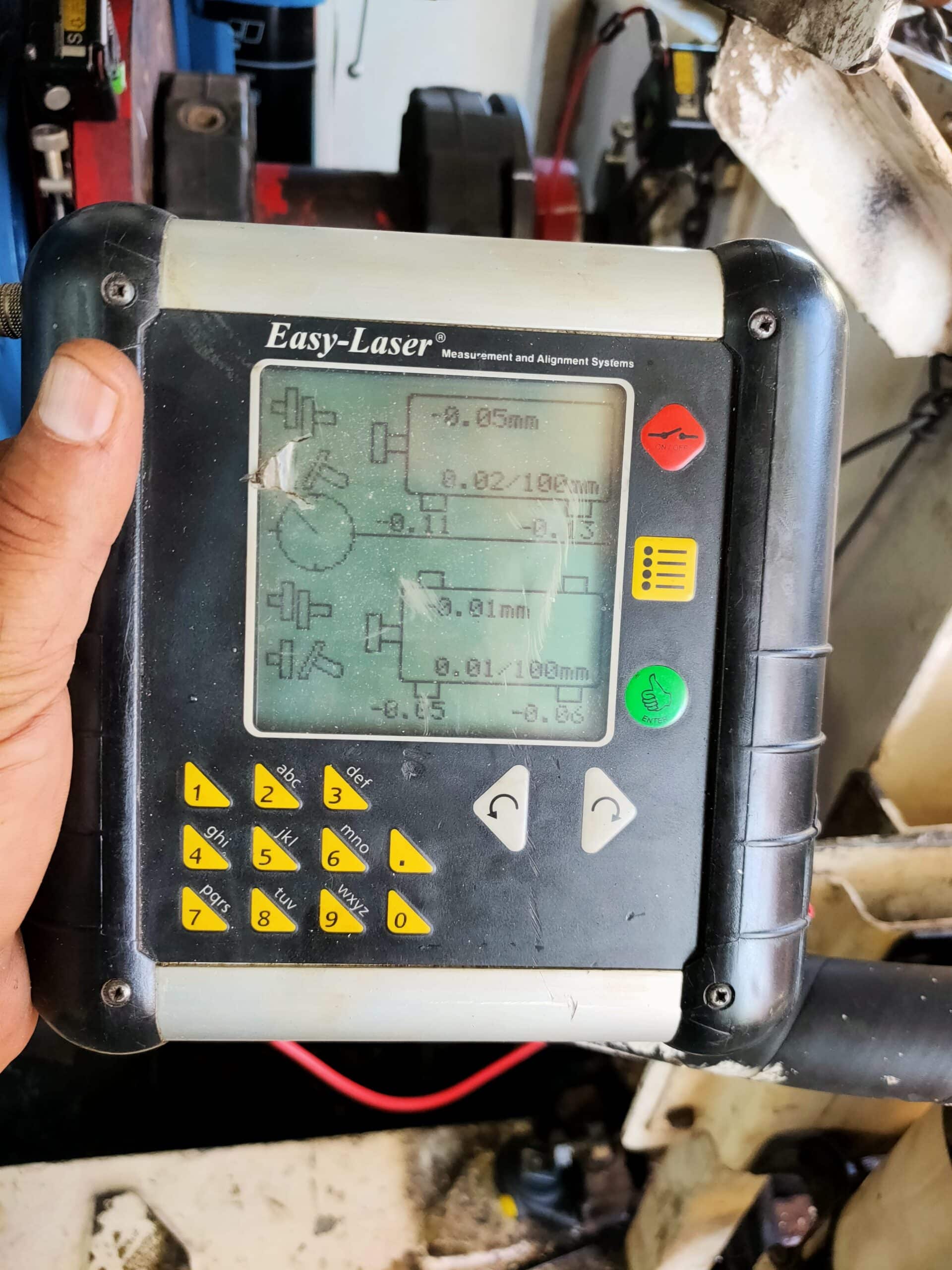

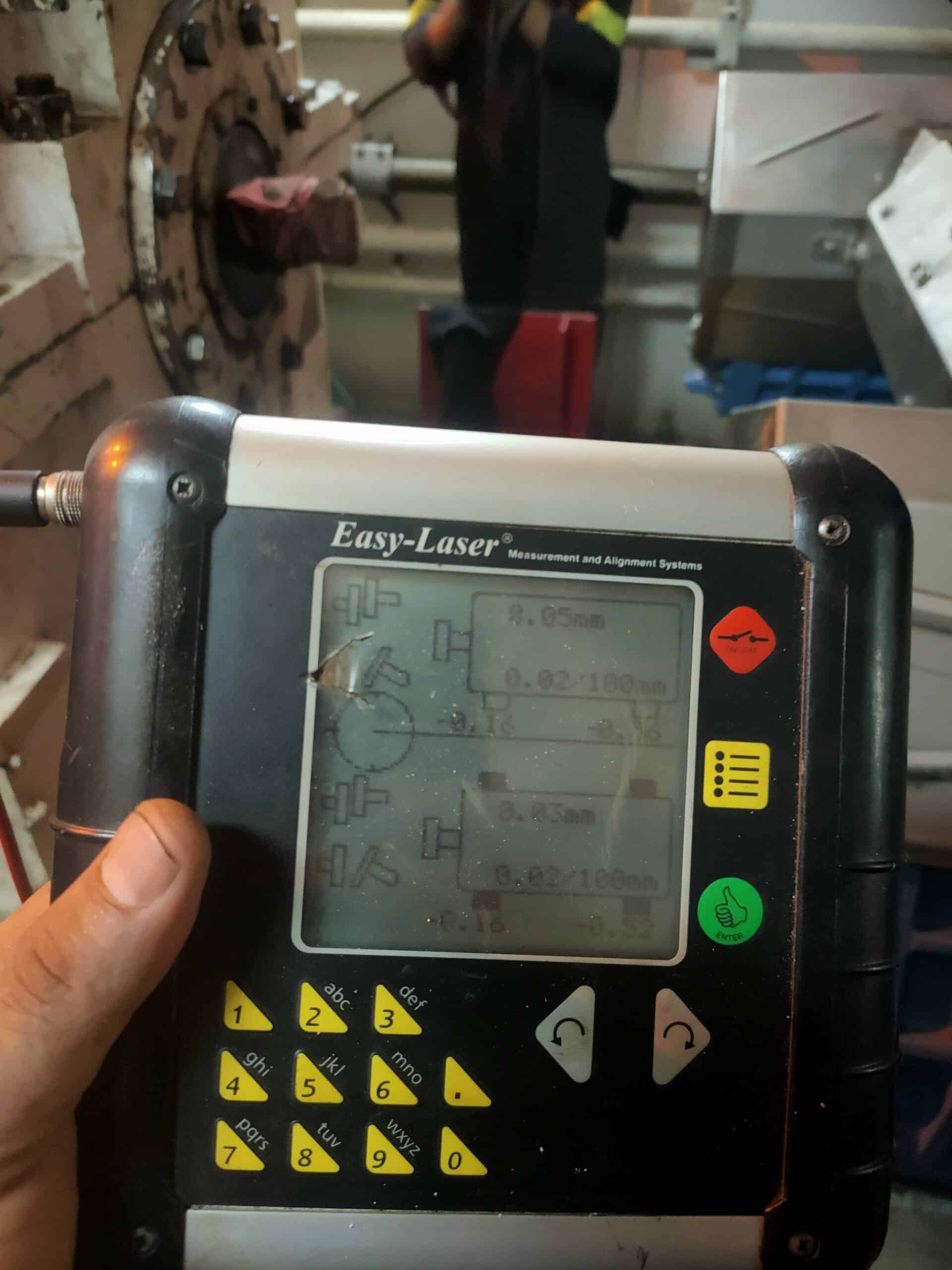

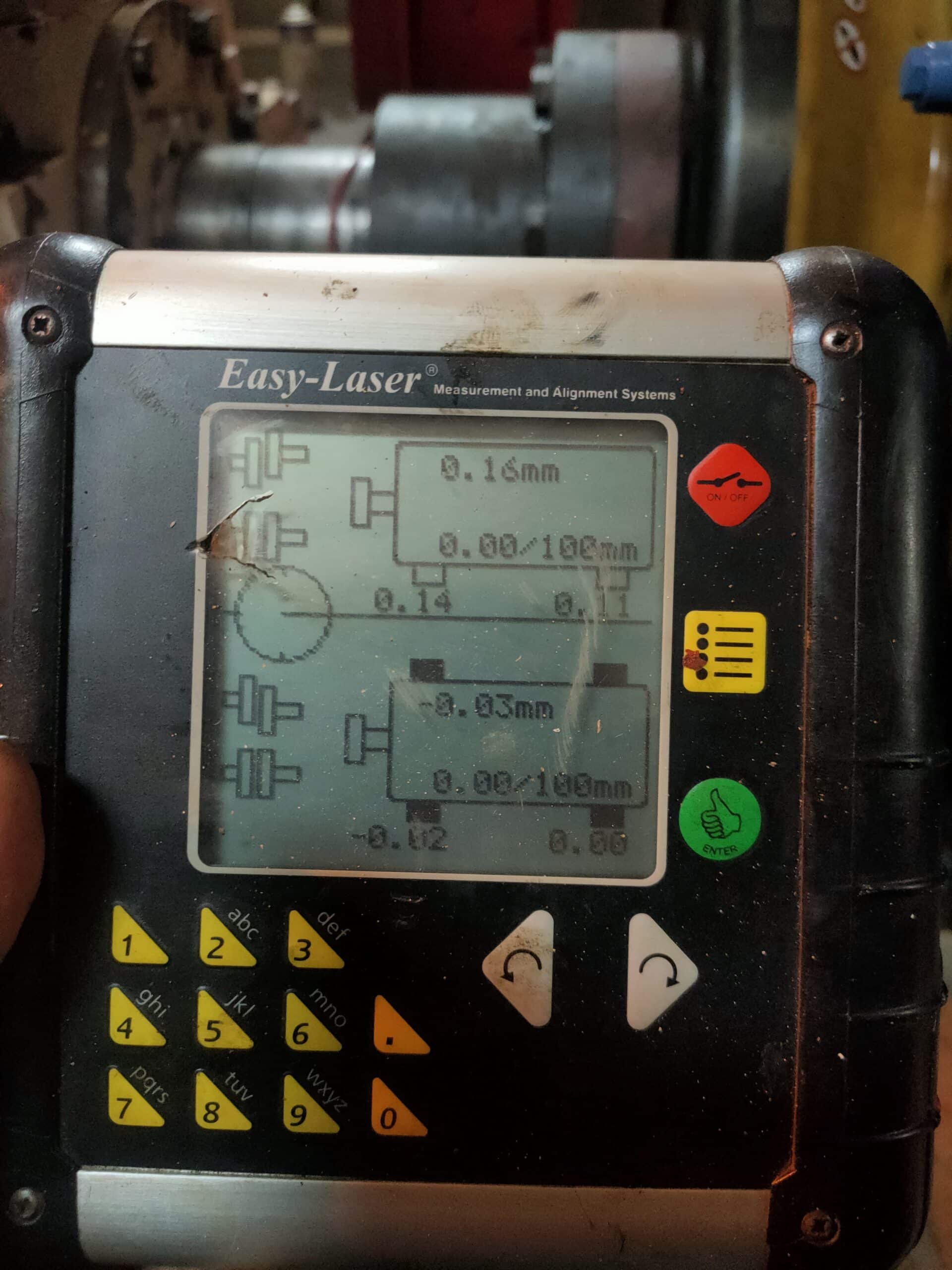

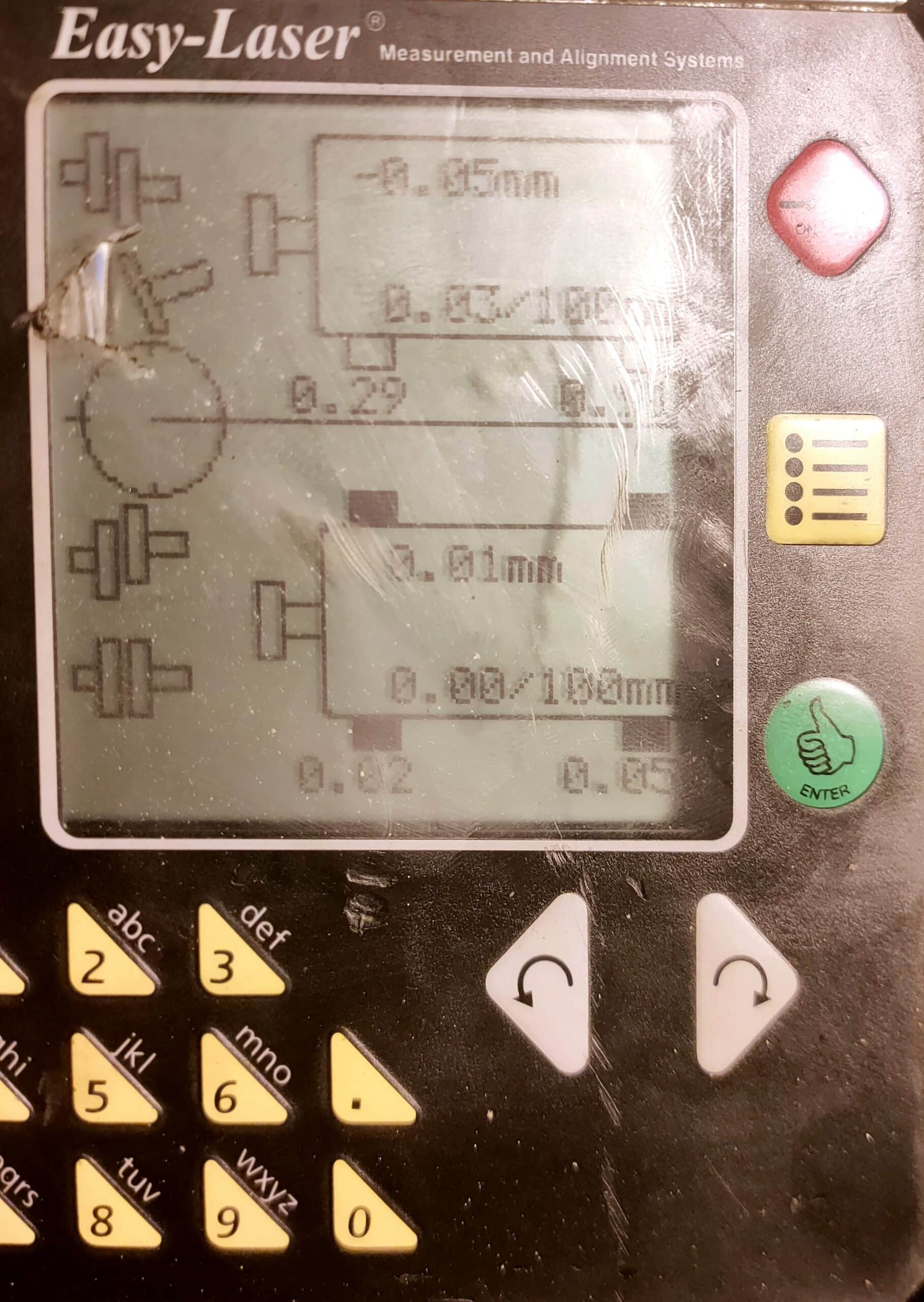

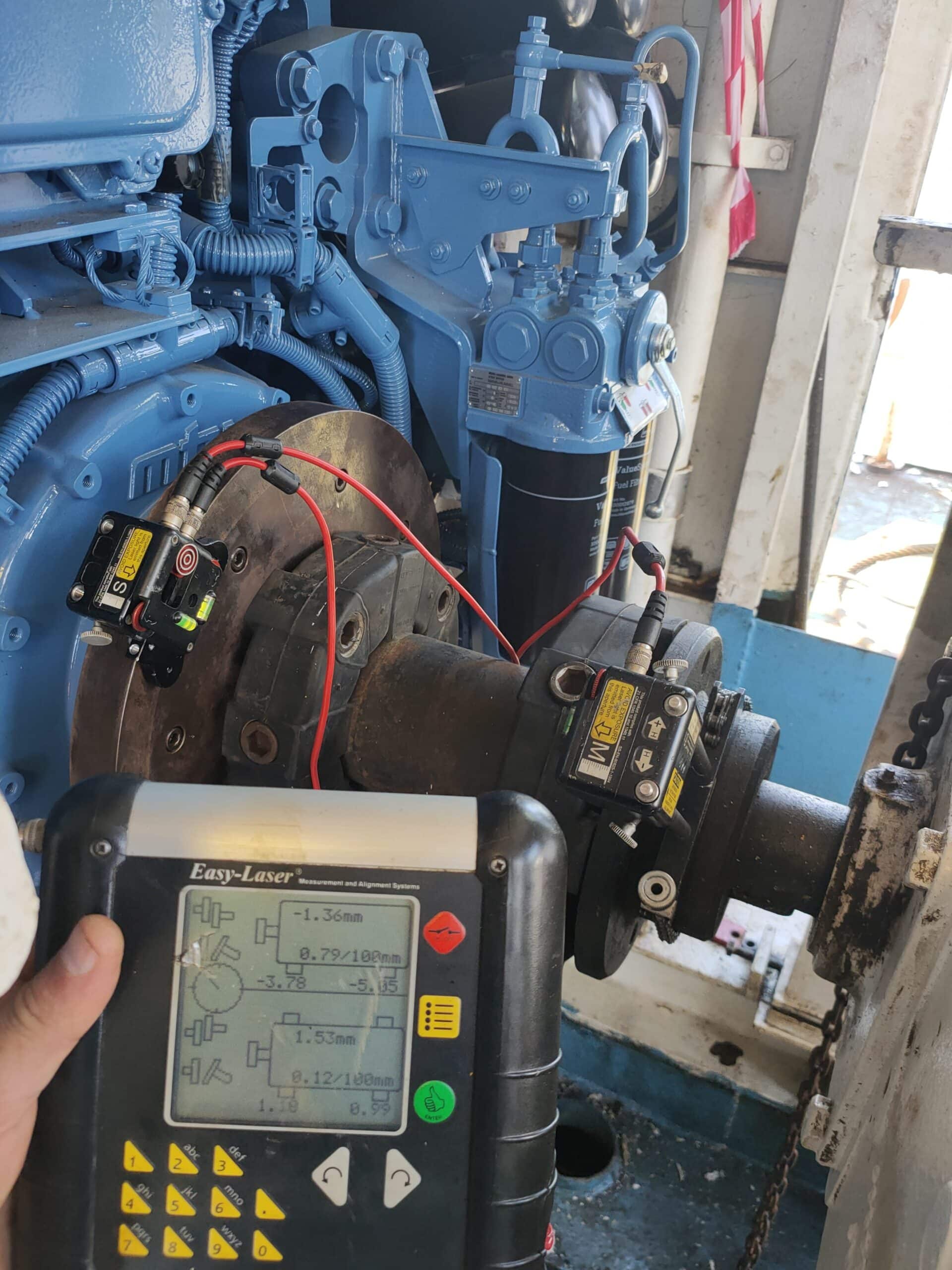

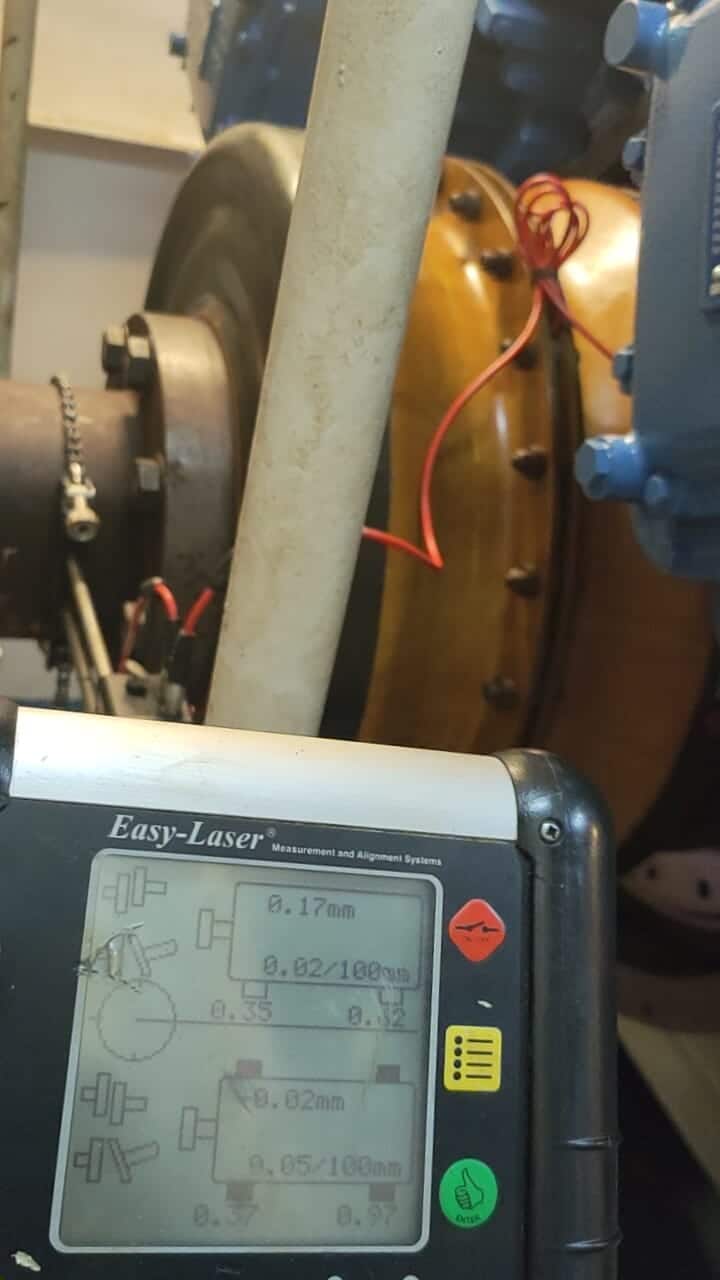

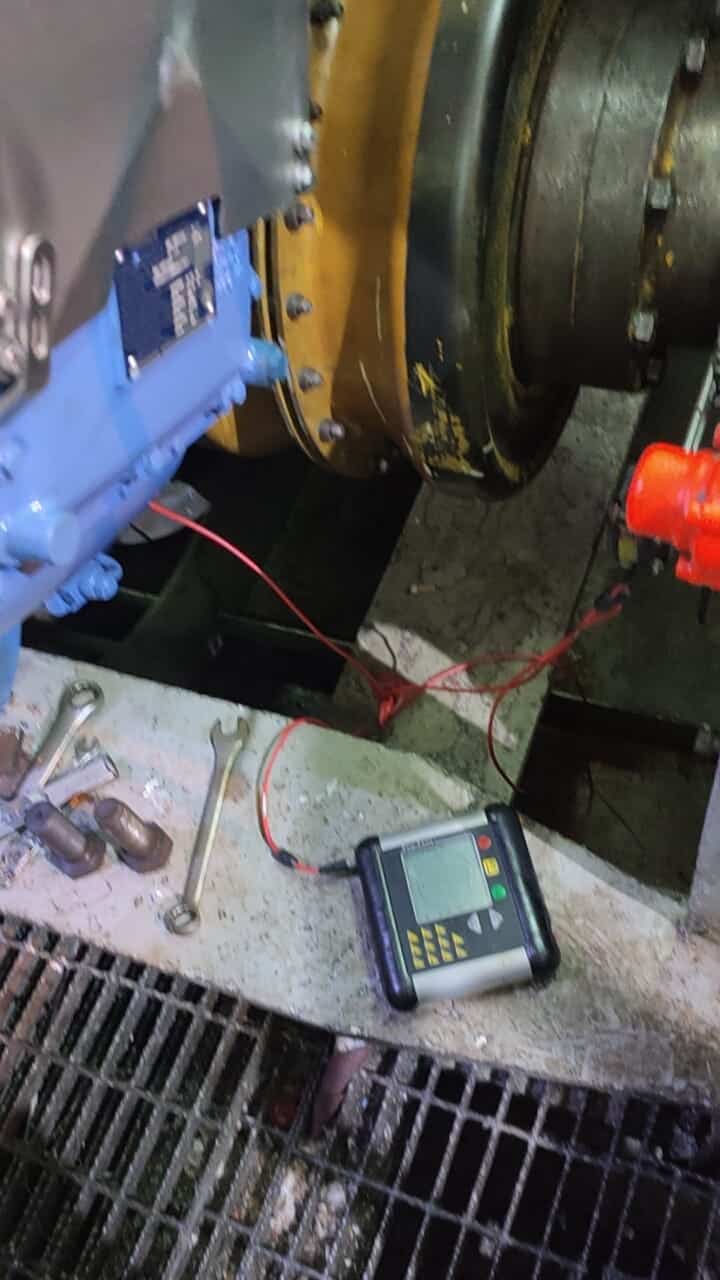

- Laser alignment.

- Dial indicator.

- Alignment using the mechanical device.

- Alignment using manual methods.

Although the method of the laser alignment is considered to be the most recent method in the world, it is not suitable for all businesses, as the use of this method is governed by a set of restrictions and factors like other methods, so we recommend choosing this method if the conditions are appropriate and also used in Marine equipment and equipment with very high speeds, which need very low permits, because this method is considered to have high costs compared to other methods.

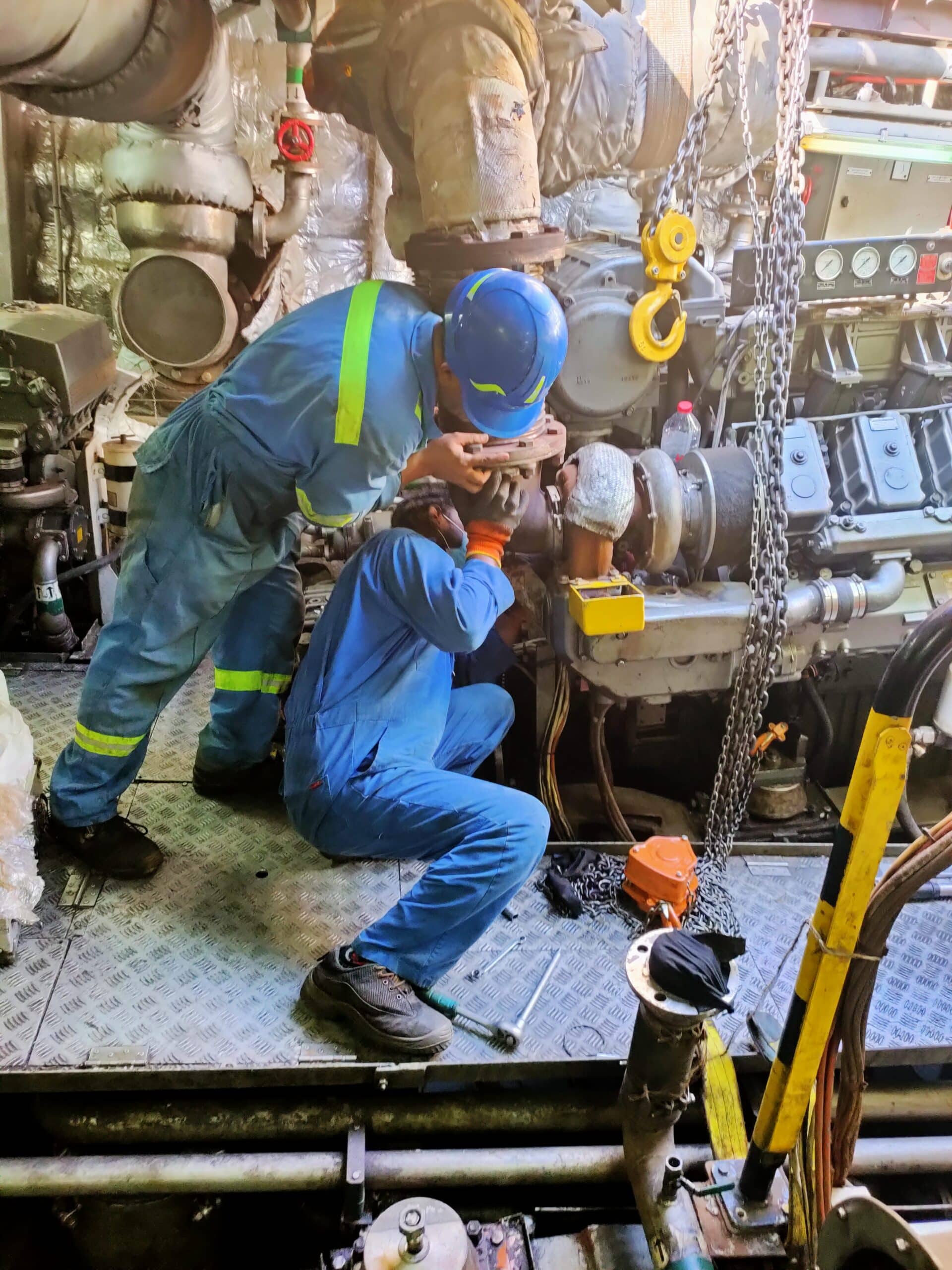

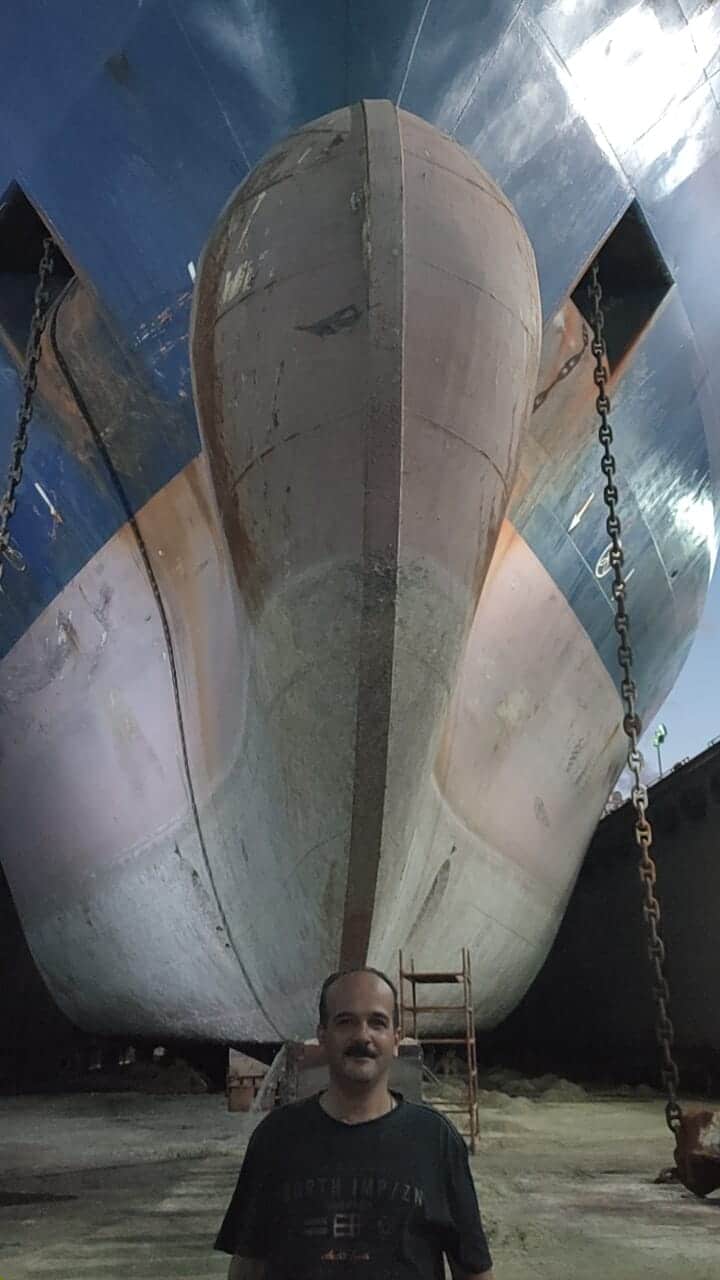

Laser Shaft Alignment Marine Repair & Maintenance

WANIS MARINE SERVICES :

Align & Chock, Laser Shaft Alignment, Line Bore Straightness, Vibration Measurements, Propeller Shaft, Rudder, Gearbox & Clutch, Crane & Hydraulic, Pumps

Shaft alignment, Ship stability, Misalignment, Drive shaft, Repair ship, ship Vibration, Ship, Ship Rudder, Ship’s wheel, boat, submarine, DURASIN, KVM, MANGANA

Ship, Boat, Yacht Repair & Maintenance :

Durasin in Egypt, Durasin in Saudi Arabia, Durasin in Oman, Durasin in Middle East, KVM in Egypt, KVM in Saudi Arabia, KVM in Oman, KVM in Middle East, Fire stop in Egypt, Fire stop in Saudi Arabia, Fire stop in Oman, Fire stop in Middle East, Mangana in Egypt, Mangana in Saudi Arabia, Mangana in Oman, Mangana in Middle East, Alignment in Egypt, Alignment in Saudi Arabia, Alignment in Oman, Alignment in Middle East.

Marine Workshop :

ALIGN & CHOCK in Egypt, ALIGN & CHOCK in Saudi Arabia, ALIGN & CHOCK in Oman, ALIGN & CHOCK in Middle East, Propeller Shaft in Egypt, Propeller Shaft in Saudi Arabia, Propeller Shaft in Oman, Propeller Shaft in Middle East, Alignment Systems in Egypt, Alignment Systems in Saudi Arabia, Alignment Systems in Oman, Alignment Systems in Middle East, Clutch & Gear Box in Egypt, Clutch & Gear Box in Saudi Arabia, Clutch & Gear Box in Oman. Clutch & Gear Box in Middle East, Hydraulic & Deck Machinery in Egypt, Hydraulic & Deck Machinery in Saudi Arabia, Hydraulic & Deck Machinery in Oman, Hydraulic & Deck Machinery in Middle East.

Marine Repair :

Rudder in Egypt, Rudder in Saudi Arabia, Rudder in Oman, Rudder in Middle East, pumps in Egypt, pumps in Saudi Arabia, pumps in Oman, pumps in Middle East, Balance in Egypt, Balance in Saudi Arabia, Balance in Oman, Balance in Middle East, Bore Alignment in Egypt, Bore Alignment in Saudi Arabia, Bore Alignment in Oman, Bore Alignment in Middle East, Vibration in Egypt, Vibration in Saudi Arabia, Vibration in Oman, Vibration in Middle East, Alignment, adjusting alignment, axes, bore alignment, vibration, vibrations, vibration analysis, balancing, dynamic balance, static balance. propeller blades, copper bushing, cutlass bearing, cutless bearing, bearing, bearings, dx bearing, blades.

Marine Maintenance :

bushings, propeller shaft, thordon, sordon, rubber, lugnam vita bushings, vibration measurements, vibration measurements devices, vibration causes treatment, wire tightening, propeller shafts, propellers, packing, stuffing box, rudder, rudders, simplex, yacht, yachts, yachts maintenance, propeller shaft overhauling, bushing bearings, shock absorber, vibration absorber, sea, marine, chockfast, absorber, hydraulic, winches, crane winches, telescopic winches, blacksmith winches, towing cranes, zodiac cranes, cranes, surface cranes, surface components, diesels , diesel engines, diesel engines maintenance, pumps, pumps maintenance, water pumps, multi stage pumps, oil, gas, fuel, Hydraulic pumps, voith Schneider, z-drive, controllable pitch propeller, variable pitch propeller, constant pitch propeller, azimuth, azipod, bow thruster, gears, gearbox, gear boxes, od box, gaskets, o-ring, o-rings,